Macroscopic examination, also known as macro test, is often accomplished at low magnification on the cross or longitudinal sections of welds to evaluate the weld quality. Moreover, the macro test is performed on fracture surface of the failed parts to determine the cause of failure and any evidence of failure modes. The macro sample is prepared using standard metallographic techniques including cutting, grinding, polishing, and etching in an appropriate chemical solution according to ASTM E407. The macrostructural properties of a weldment are then assessed according to the relevant welding standard such as ASME and AWS.

ABEN metallurgical engineering team offers the following macroscopic examination services according to the relevant standards:

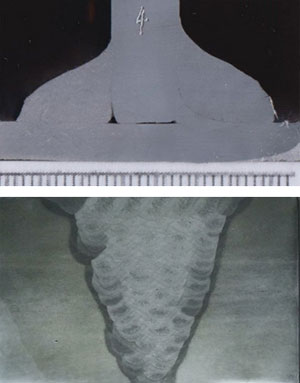

Weld cross-section examination to reveal:

- Weld geometry.

- Weld profile, weld passes and sequence.

- Internal discontinuities such as voids, porosity, inclusions, slag, cracks, lack of weld penetration, and lack of sidewall fusion.

- Extent of heat-affected zone (HAZ).

- Surface defects such as undercut, inconsistent weld bead profiles, excessive throat, concave or convex weld, and weld toe angle.

- Joint geometry defects such as root gap, root face, and misalignment.

Fractogrphic examination to identify:

- All sorts of anomalies, service damage, wear marks, and cracks.

- Corrosion damage and morphology of corrosion products.

- Mechanism of fracture and any evidence of failure modes.

Feel free to contact us for more information about our positive material identification services or to request a quotation.